I’ve been looking to dip my toes into the 3D printing pool for a week or so now. I really needed a project that would be a good excuse to print some parts. I decided to start with the design of a magnetically fastened camera mount that would use a Maxwell kinematic coupling. I love kinematic couplings and used them in some cool automation applications in the past. They’re a great way to repeatably and accurately locate tooling or fixtures that need to be easily removed.

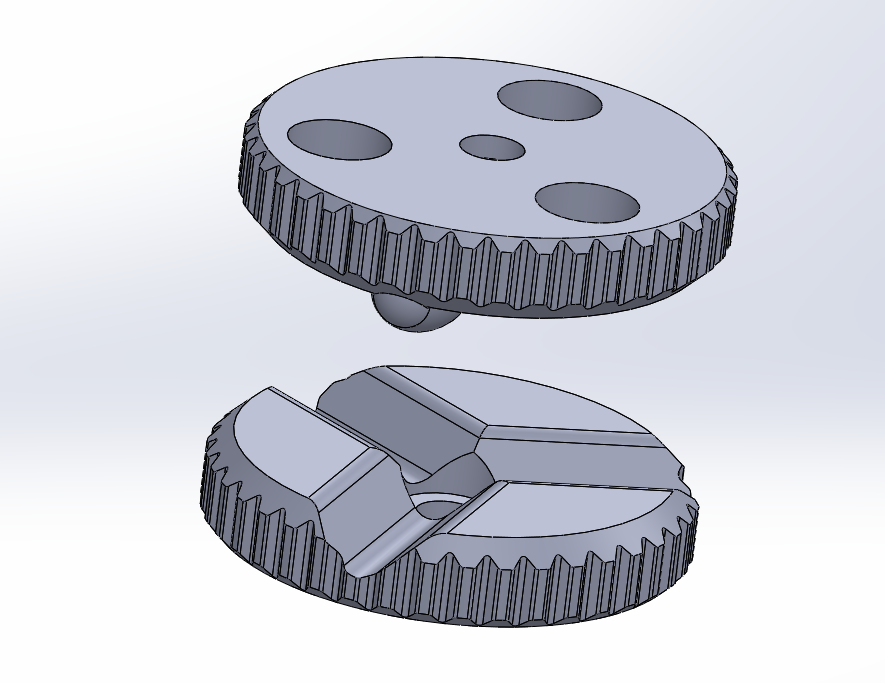

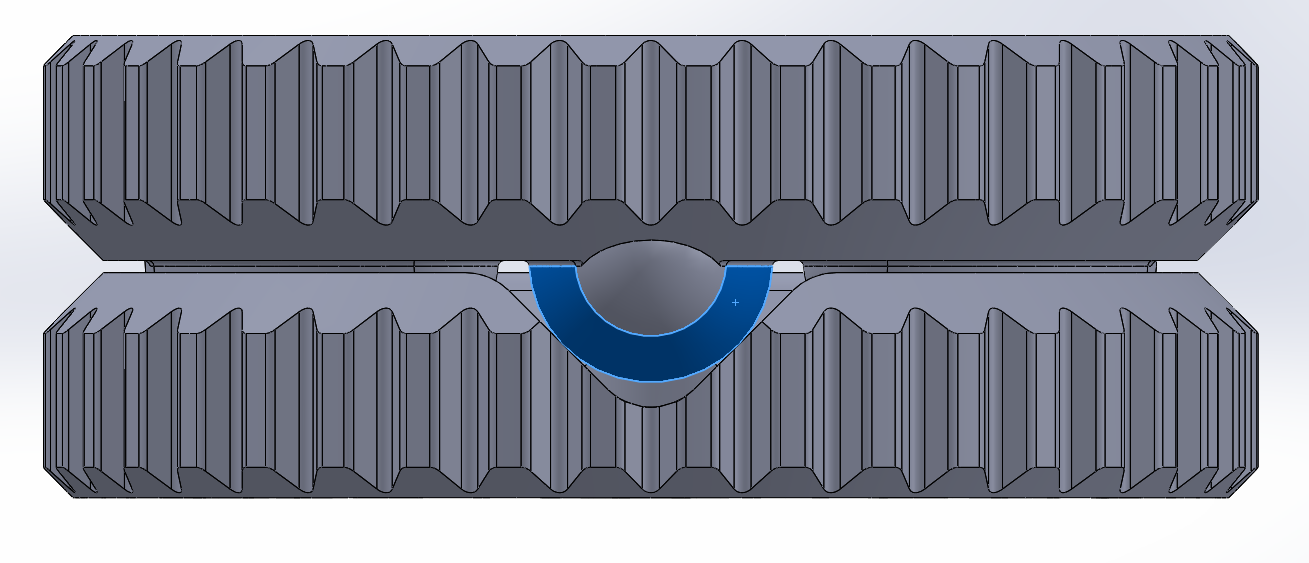

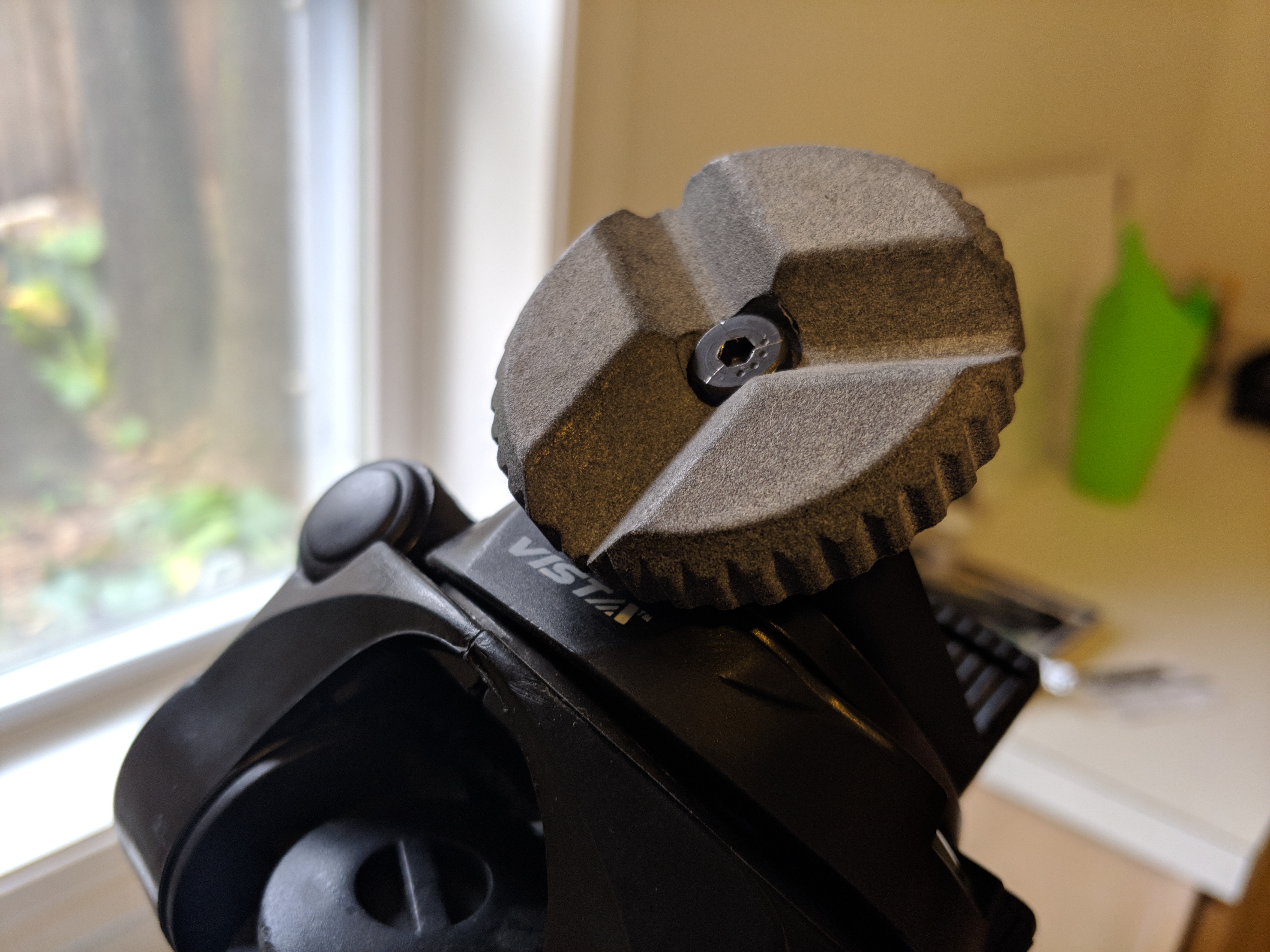

I started off with the design in Solidworks going through a few iterations of the magnet spacing and contact surfaces. The V-grooves in the base part accept a roundish spherical feature in the mount for accurate location. Three magnets are located in circular pockets in both the base and mount piece. The center of each piece has a counterbore to accommodate a socket head cap screw for the standard 1/4-20 camera thread.

I shipped the files off to Shapeways to try out their “professional plastic” material which is really HP’s Multi Fusion Jet process which I was not familiar with. As an aside, I think I’m going to rely on printing services in the short term before I invest in a printer. I’m really tempted to get the AnyCubic Photon but I think I would be limited by the build volume. Services will give me a lot of flexibility for experimentation.

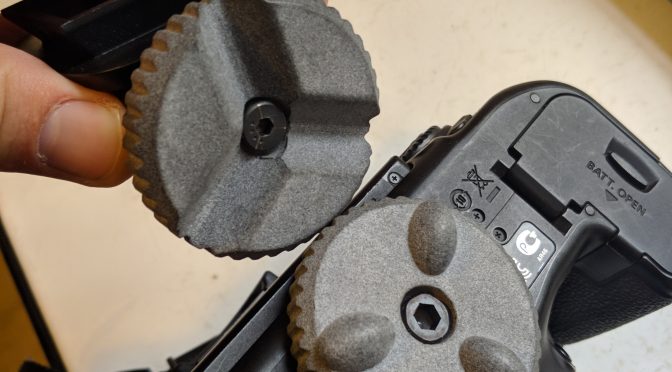

I received the parts a few days later and I was impressed with the results. The plastic had a nice smooth finish and matte appearance. The prints were close to being dimensionally accurate but their was a weird curled lip on a few of the sharper edges. The assembled pieces didn’t quite hold the small 0. 020″ gap I designed in between the two halves. This indicates that the V-grooves and spherical contact features are slightly off in size.

I assembled everything including gluing the magnets into the parts. The pockets I designed for the magnets had a lot of extra clearance because I wasn’t sure how accurate the inner diameter would print. In the future I would like to get this to a press fit but in the short term adding some super glue is an easy assembly step.

The design worked great! Snapping the pieces together has a nice satisfying feeling and overall the design is practical and functional. In the next version I would like to increase the magnetic holding force because it’s at the limit when holding my 70D.

Overall I’m pleased with the project and the design of the mount. I think there a lot of room to explore this application in the camera mounting space. The magnetic coupling is a novel approach and I think the design could be a great solution to mounting smaller GoPros. Stay tuned!