SLS prints can be very flexible. The key is designing features that will allow the typical Nylon PA 12 material to flex where needed. 3D printing makes it very easy to pattern small intricate flexure features across a part. Each individual flexure only needs to bend a tiny amount to contribute to a larger overall bending across a part. The part is SLS printed in a static unflexed state and is immediately flexible when removed from the supporting powder.

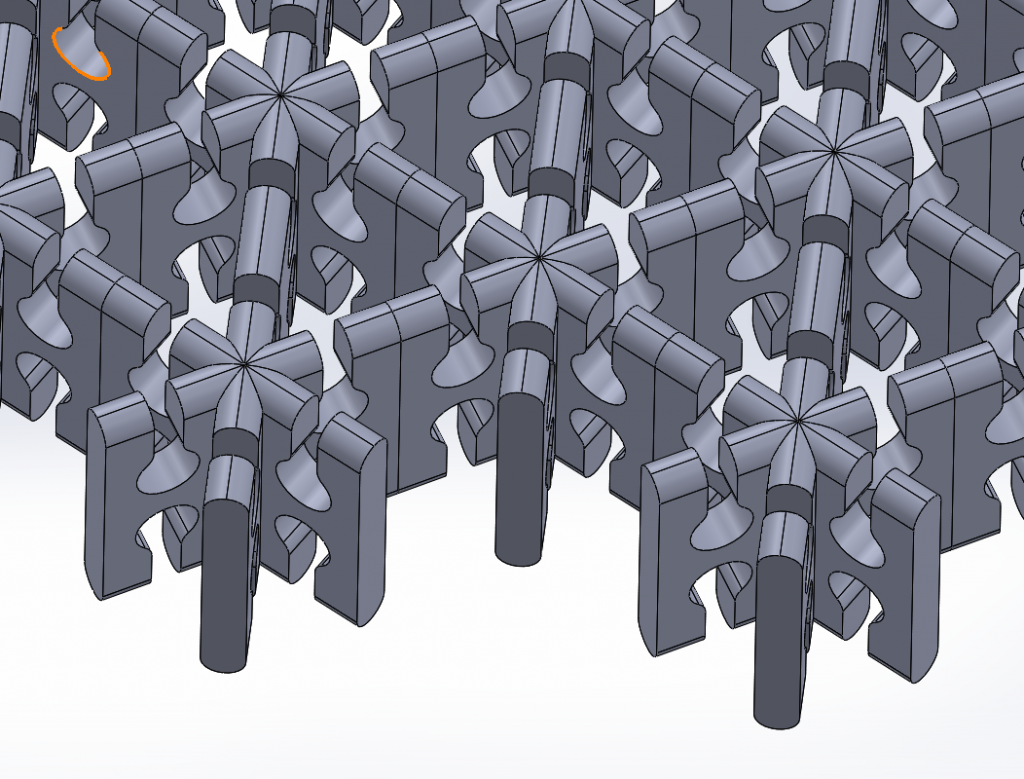

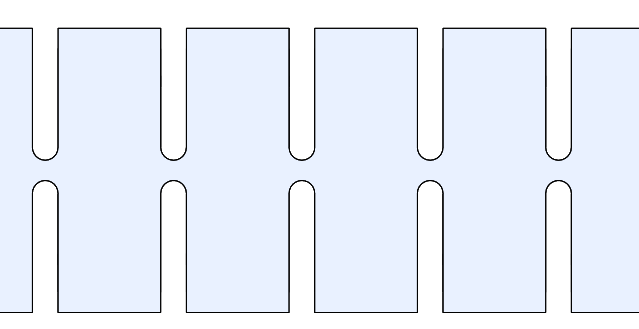

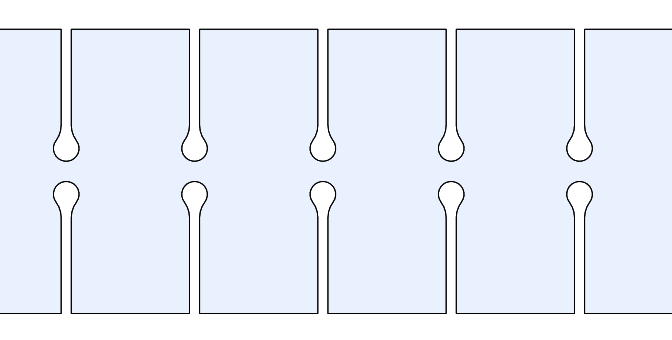

In its simplest design, a flexure feature will be a thin piece of material joining two larger bodies. When a bending moment is applied between the two bodies, the thin piece of material is the weakest structural link and bears all of the deflection.

If the flexure bends too far the material will break under strain. The flexure can be designed with contact points around the joint to minimize the bending. This helps to limit the bending strain by limiting the relative deflection. Tension can continue to build across the flexure joint as the contact points will act as a fulcrum. These joints aren’t fragile but will fail under enough load.

Similar flexure designs can be created in metal but often with an expensive wire EDM process. 3D printing makes it very inexpensive to design intricate flexure joints and pattern them without the concern for manufacturability.

Some experimentation is required for the flexure design but the key is understanding the minimum feature sizes that can be printed. You need to consider the minimum supported feature size and the minimum gap width. These parts were printed with Shapeways Versatile Plastic which is really EOS SLS. The flexure is 1.0mm at its thinnest point and the contact gap width is 0.5mm.

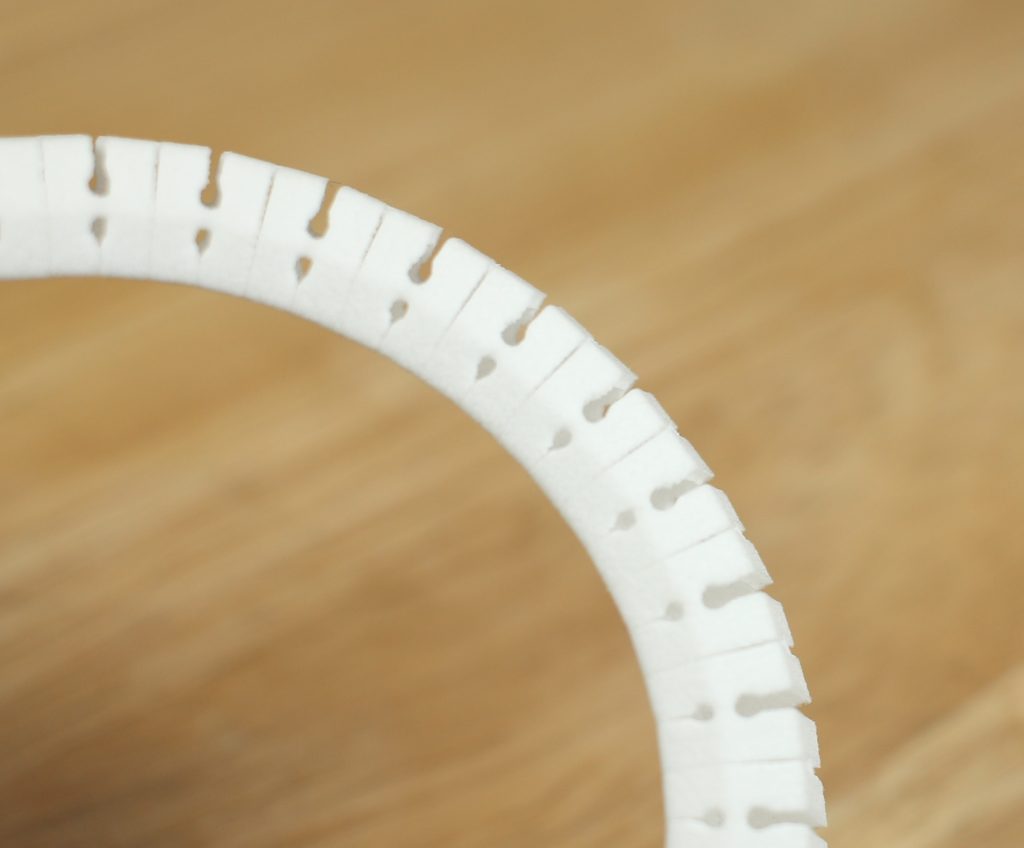

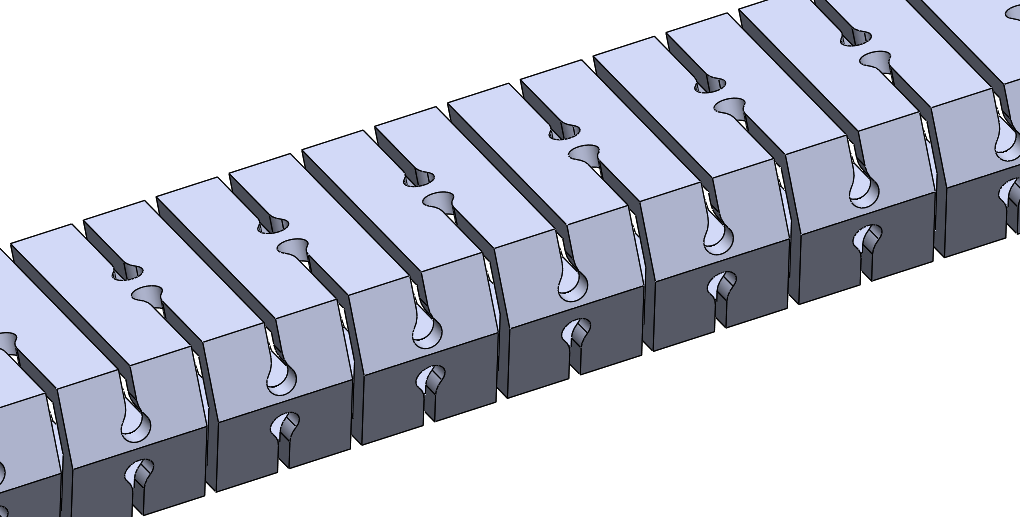

One simple flexure design can be patterned across a part to introduce bending. The part can only bend in the direction of the flexure features so you often need flexures in different orientations across the part.

This track part was designed with a hollow cross section to feed parts into a pick and place machine. It has flexures in two planes. The spacing of the flexure features controls the bend radius of the track.

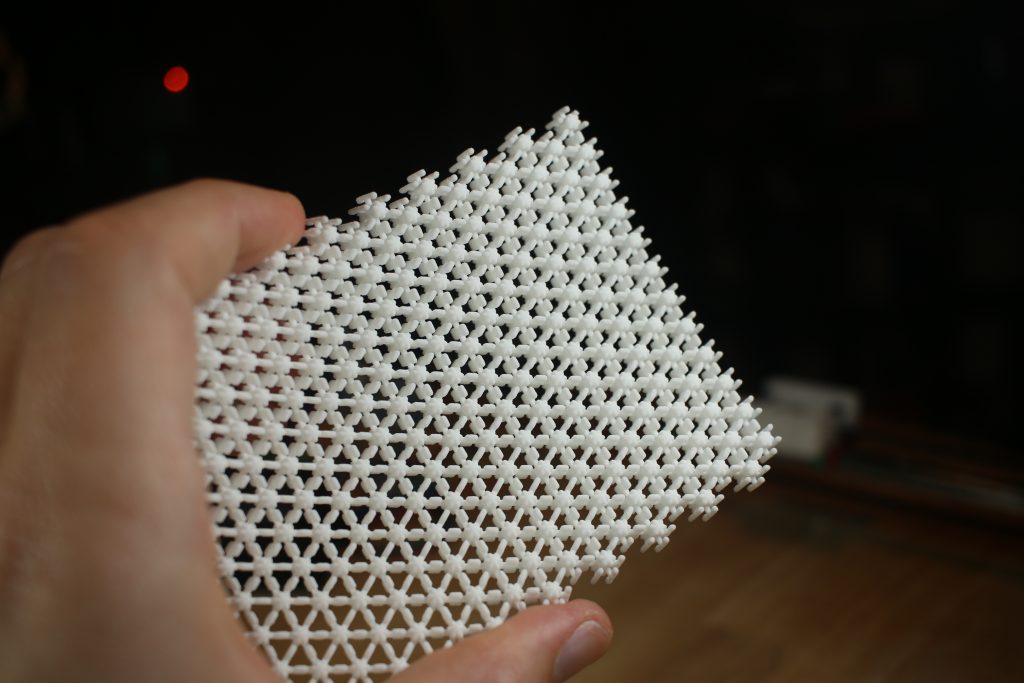

This simple test piece has flexures in three planes and was designed to be as flexible as possible. It’s application of the same flexure design patterned across a part.